Large-scale deployments demonstrate that AI-powered anomaly detection through Dynacard Classification is a must to improve oil production, equipment reliability, and maintenance cycle time.

Harnessing big data is one of the upstream industry’s biggest hurdles in optimizing wells that are already producing. Dynacard Classification helps unlock valuable insights from tremendous amounts of data scattered among millions of files in multiple formats and programs over the years. This leaves critical information locked away due to inconsistent data structures and no central repository—or, in some cases, no data was ever collected.

The good news is that, as an industry, we’re getting better at utilizing and unlocking historical data to improve production and reduce maintenance cycle time. These efficiencies are helping operators to better manage cash flow and maintain the profitability of producing assets, particularly during times of commodity price volatility. The bigger challenge in achieving improved performance remains deploying new processes and technologies efficiently across an installed base of aging assets and functional groups across an entire organization.

Introducing Cognitive Computing for Oil and Gas

Cognitive computing is a subfield of artificial intelligence (AI) that refers to systems that aim to simulate human thought processes and reasoning to interpret data and learn from interactions. Unlike traditional programmed systems, cognitive computing solutions can analyze large amounts of unstructured data from various sources and identify patterns and insights. This ability to mimic the natural learning process makes cognitive computing well-suited for domains like the upstream sector, where huge amounts of complex data can be analyzed quickly to find solutions. Then, the system can make evidence-based recommendations on the right action to take.

Cognitive Card Recognition

Cognitive Card Recognition (CCR), a key component of Ambyint’s InfinityRL™ rod lift optimization solution, is a suite of machine learning models designed to characterize both normal and non-normal dynacards. CCR effectively automates the process of dynacard classification and inspection, an activity that is time-consuming and can only be accurately accomplished by highly skilled staff. CCR represents a core set of functionality within Ambyint’s InfinityRL™ rod lift optimization platform.

CCR was developed by building unique machine learning models for each card type. Rod Lift subject matter experts were paired with data scientists skilled in machine learning pattern recognition techniques to develop models capable of accurately classifying card shapes. Across all card models, millions of expert-labeled cards were required to accurately classify card shapes. This activity was undertaken by Ambyint SMEs over a period of years, with thousands of additional labeled cards added on a monthly basis to consistently maintain and improve model accuracy.

The business value of CCR to an oil/gas producer is significant. Inspecting and classifying dynacards, including identification of dynacards that represent major operational issues, is crucial to better understanding the current health and efficiency of the rod lift system. When time is short, operations and engineering staff must prioritize their time to focus only on the highest priority operational issues. Typically, this means that all available dynacards are not inspected, resulting in critical operational issues not being identified until there has been a significant impact on production. Fully automating the workflow translates into substantial time savings for operations and engineering staff. Additionally, automating the workflow enables all available cards to be inspected and classified, ensuring no critical issues are missed due to lack of time.

CCR enables operations teams to move from a highly reactive state—only addressing critical issues after production has already suffered—to a more proactive state, empowering operations teams with information early to warn them of impending problems so that they can take action before the business suffers the consequences of a catastrophic problem. In many cases, CCR alerts users to operational issues weeks or even months earlier than they would otherwise have identified them. The result is a reduction in deferred production and well downtime, potential reduction in workover costs, and substantial time savings for overtaxed operations teams.

Ambyint’s CCR suite is robust, featuring the most common non-normal dynacard shapes. CCR insights are delivered to users in multiple ways within the InfinityRL™ solution to ensure that these important insights are highly visible to users. Critically, these card shapes are descriptive enough to allow operators to quickly evaluate corrective actions.

Today, CCR includes twelve of the most common non-normal dynacard shapes, but will soon be adding two more card types. Not only does Ambyint continue to add additional anomalies, but the accuracy of the models is constantly improving through regular incorporation of additional labeled data and model re-training. All of the CCR models currently have an accuracy of 85% or higher, with some models closer to 95% accuracy.

The full set of dynacard types that Ambyint currently provides (twelve) and will soon provide (two) as a part of its CCR suite is included below.

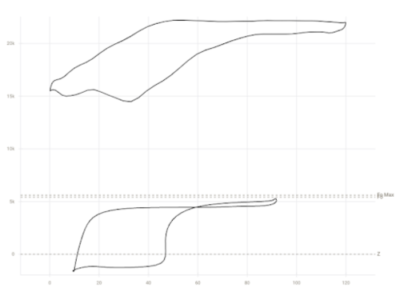

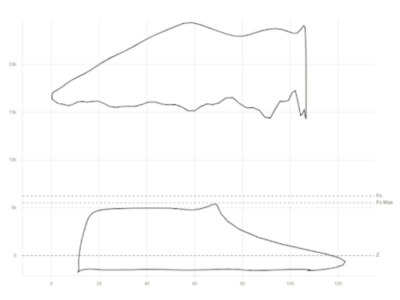

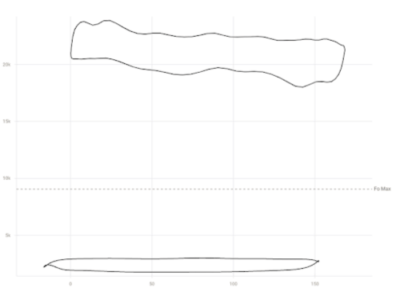

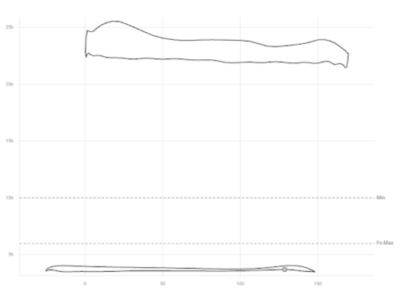

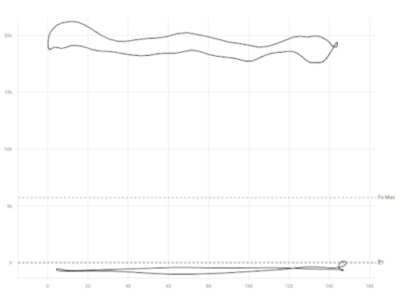

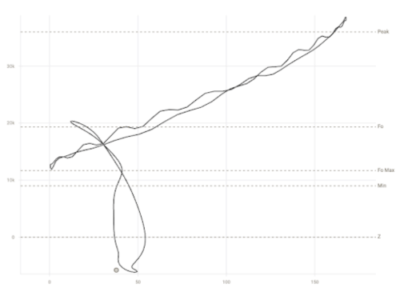

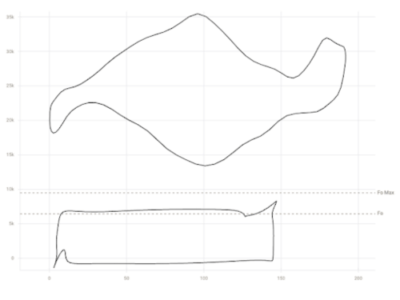

Fluid pound in an oil well occurs when the downhole pump reaches the fluid level but cannot fill completely, often due to insufficient fluid inflow. This leads to inefficient pump operation, causing mechanical stress and reduced oil production.

Gas interference in an oil well happens when excessive gas enters the downhole pump, disrupting the normal flow of fluids and reducing pump efficiency. This causes erratic pump behavior, leading to lower oil production and potential damage to the equipment.

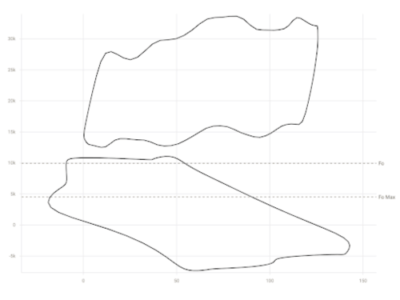

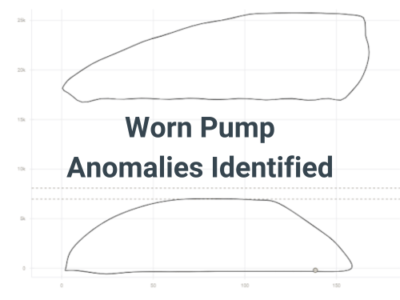

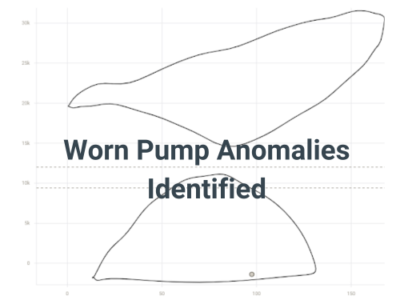

A worn pump in an oil well occurs when the pump components, such as valves or plungers, experience wear over time, reducing their ability to move fluids effectively. This leads to decreased oil production, increased energy consumption, and potential equipment failure.

A delayed traveling valve occurs when the valve in the downhole pump fails to open and close promptly, often due to mechanical wear or improper seating. This causes inefficient fluid movement, reducing pump capacity and oil production.

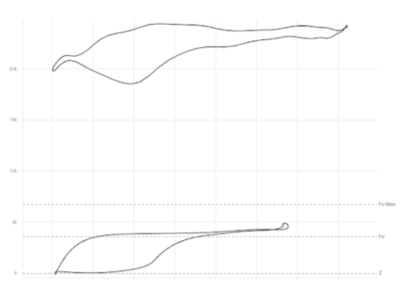

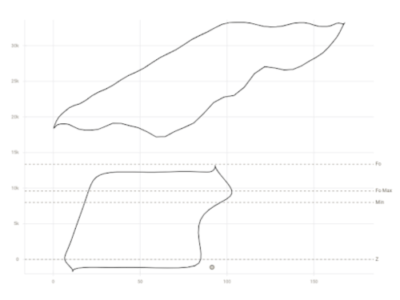

A “hole in barrel” occurs when there is a physical breach or wear in the tubing or pump barrel where the sucker rods reciprocate to lift fluid from the well.

A hole in the tubing occurs when the tubing in an oil well becomes damaged or corroded, allowing fluid to escape before reaching the surface. This results in loss of production efficiency, potential contamination of the wellbore, and added strain on the pumping system.

A standing valve stuck open occurs when the valve at the bottom of the downhole pump fails to close properly, allowing fluid to flow back into the well. This reduces the pump’s ability to lift fluid to the surface, leading to decreased production and increased energy consumption.

A rod part in a rod lift well occurs when one or more sucker rods break or become disconnected in the production string.

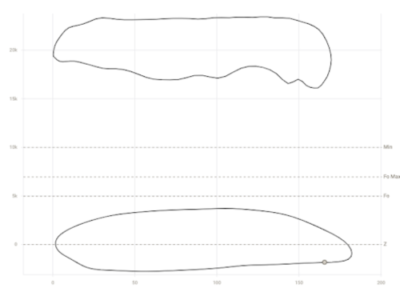

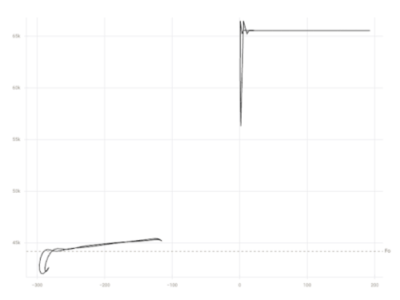

A stuck pump occurs when the downhole pump becomes immobile due to mechanical issues, debris, or scale buildup in the wellbore. This prevents the pump from moving fluids effectively, halting production and potentially causing damage to the well equipment.

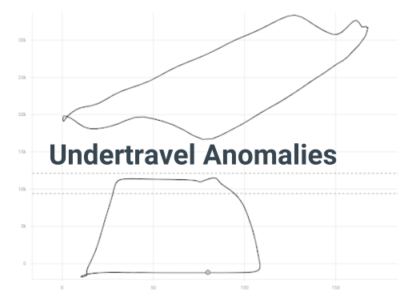

Plunger undertravel occurs when the plunger in a rod lift system does not complete its full stroke, often due to insufficient fluid levels or mechanical issues. This limits the pump’s capacity to lift fluids, reducing oil production and increasing stress on the equipment.

Bad data in oil well operations refers to inaccurate or incomplete information from sensors, gauges, or monitoring systems.

Distorted dynacards provide misleading information about pump performance, making it difficult to accurately diagnose well problems.

Coming Soon

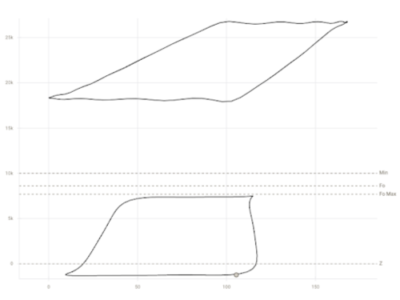

Tagging in an oil well occurs when the plunger or rod string hits the bottom of the wellbore or pump. This contact when unaddressed can cause mechanical damage, equipment wear, and inefficient pumping.

Paraffin buildup occurs when waxy substances from crude oil solidify and accumulate in the tubing. This restricts fluid flow, and can lead to blockages and reductions in production efficiency.

Case Studies: Cognitive Card Recognition in the Field

CCR is a critical part of the daily workflow for users of Ambyint’s InfinityRL solution. CCR, paired with regular surveillance of wells, results in rapid identification and remediation of operational issues to reduce well downtime, reduce deferred production, and improve equipment reliability. The two case studies below provide real-world examples for CCR’s identification of an emerging operational issue, the action taken to remediate the issue, and the result.

CCR Case Study 1

Hole in Barrel

This case study provides a real-world example of how CCR anomaly detection supports users to identify critical operational issues more quickly so that action can be taken to remediate the issue. In this example CCR identified a Hole in Barrel.

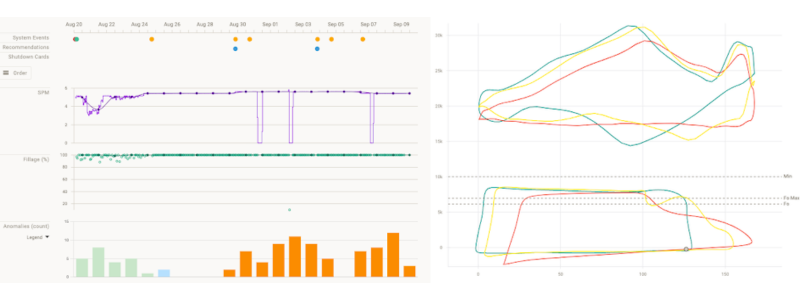

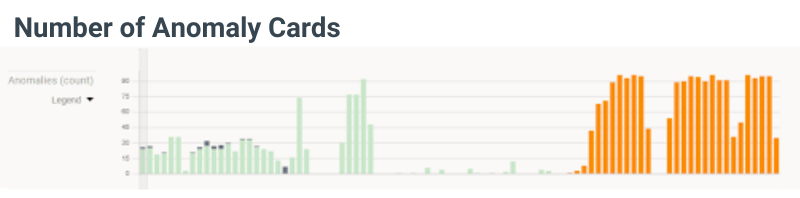

In the well example below, CCR detected a Hole in Barrel (see orange in vertical bar chart) as soon as the issue began to show on dynacards (Aug 28) and immediately reported the issue to users. A Hole in Barrel causes loss of fluid at the pump, typically resulting in reduced oil production and higher operating costs. Fortunately, this Hole in Barrel was identified before there was any significant impact on oil production. Due to the CCR insight, the operator has put the well on the workover schedule to get ahead of the expected loss in oil production.

The benefits that resulted from CCR include the following:

- Reduced the cycle time to identify this issue – moving from reactive to proactive

- Minimized deferred production that would normally occur

CCR Case Study 2

Rod Part

This case study provides a real-world example of how CCR anomaly detection supports users to identify critical operational issues more quickly so that action can be taken to remediate the issue. In this example CCR identified a Rod Part.

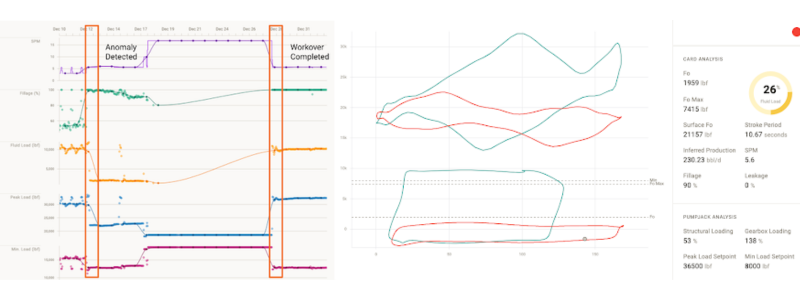

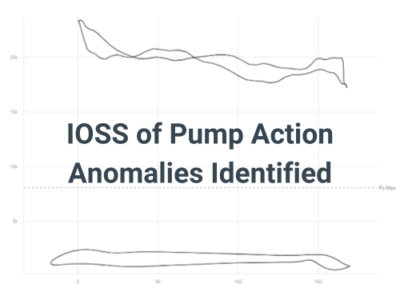

In the well example below, CCR detected a Rod Part on Dec 12 and immediately reported the issue to users. A Rod Part typically results in a complete loss of pump action and can cause further damage to downhole equipment if the well is not shut down. CCR enabled this user to identify the issue 1-2 days more quickly and shut in the well, and schedule a workover to replace the parted rods. A workover was completed on this well 15 days after the issue was identified by CCR and the well was soon back on the production trend (~200 BLPD) immediately prior to the Rod Part.

The benefits that resulted from CCR include the following:

- Reduced failure cycle time (time from issue to remediation complete) by 1-2 days

- Reduced deferred production by 1-2 days

- Minimized further equipment damage

The Integration of CCR and Autonomous Setpoint Management

In 2017 Ambyint introduced its Autonomous Setpoint Management (ASPM) functionality for plunger and rod lift applications. Its suite of artificial intelligence models was designed to assess well and equipment parameters that help determine whether a well is running optimally. Today, the system provides users with recommended setpoints based on CCR for manual or fully autonomous implementation of setpoints to achieve dynamic well optimization. In either scenario, Ambyint’s InfinityRL™ solution provides full transparency of setpoint recommendations to ensure users are aware of actions taken. For field staff managing pumping units, Ambyint’s anomalies offer a better visual representation of which wells have potential issues and may require physical intervention.

The two case studies below provide real-world examples of the ways in which CCR and ASPM work together in Ambyint’s InfinityRL™ solution to identify non-normal operating conditions and automate the implementation of setpoints to remediate or at least compensate for the sub-optimal operating condition.

CCR & ASPM Case Study 1

Anomaly Detection Extends Well’s Life

This case study provides a real-world example of how CCR anomaly detection works together with ASPM to identify an operational issue and take action to compensate for the operational issue. In this example ASPM classified the well as underpumping due to a worn pump, identified by CCR.

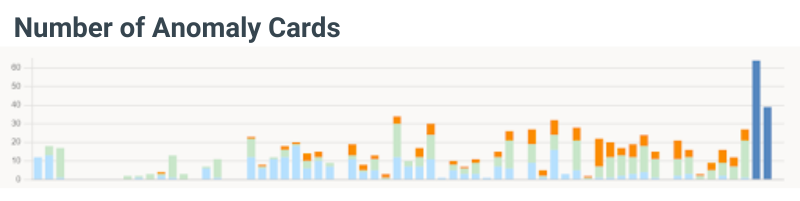

In a typical worn pump scenario, production slowly falls as the pump becomes less effective at lifting fluid. However, with CCR and ASPM, when CCR identified a worn pump (see orange in vertical bar chart), over a period of two months nine speed-up recommendations were automatically implemented, increasing max working speed from 4.5 SPM to 6.0 SPM. Instead of reduced production week over week, oil production was maintained as the well was slowly sped up by ASPM. Finally after two months of an increasingly severe worn pump, the pump finally failed, experiencing a complete loss of pump action (see dark blue in vertical bar chart), with oil production falling to zero.

The benefits that resulted from CCR and ASPM working together include the following:

- Maintained oil production rather than losing oil production

- Extended useful life of equipment by additional 2 months

CCR & ASPM Case Study 2

Anomaly Detection Prevents Loss of Oil Production

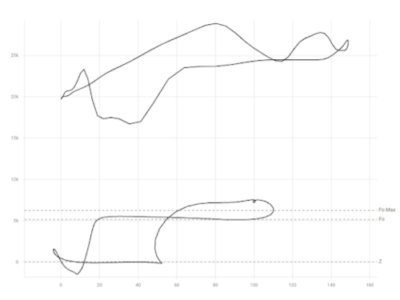

This case study provides a real-world example of how CCR anomaly detection works together with ASPM to identify an operational issue and take action to compensate for the operational issue. In this example ASPM classified the well as underpumping due to undertravel and a worn pump, both of which were identified by CCR.

In typical undertravel and worn pump scenarios, production slowly falls as the pump becomes less effective at lifting fluid. However, with CCR and ASPM, when CCR identified first undertravel (see light green in vertical bar chart) and then a worn pump (see orange in vertical bar chart), over a period of two months twelve speed-up recommendations were automatically implemented, increasing max working speed from 3.1 SPM to 5.5 SPM. Instead of reduced oil production week over week, oil production was maintained until the last few weeks of operation, as the well was slowly sped up by ASPM. Finally after two months of an increasingly severe worn pump, the pump finally failed, experiencing a complete loss of pump action, with oil production falling to zero.

The benefits that resulted from CCR and ASPM working together include the following:

- Maintained oil production rather than losing oil producti

- Extended useful life of equipment by additional 2 months

Looking Ahead

Ambyint’s CCR has proved invaluable for operators utilizing its InfinityRL™ solution, where inefficiencies can quickly be recognized, maintenance can be better managed, and wells can be autonomously optimized. Looking ahead, the company is working to refine its existing models, but is also developing additional card anomalies.

The deep insights offered by Ambyint’s InfinityRL™ solution are dramatically changing the way companies operate. Faster decisions lead to better efficiency and reduced operating costs, while new insights mean new opportunities to deliver value. North American operators can and should expect to get better production, reliability, and efficiency out of their wells.