Your Partner in AI-Powered Production Optimization

Elevating Performance in Well Management

Production operators, optimizers, and engineers manage extensive well portfolios, often focusing on a limited number of high-priority wells, leaving many under-optimized. Our AI-powered platform helps lean teams optimize every well daily, providing enhanced visibility and efficient problem-solving at scale. This allows experts to tackle complex challenges, driving better outcomes and maximizing efficiency.

Ambyint optimizes production across various well types, delivering consistent and measurable improvements in output.

Boost Productivity

Reduce workloads, unnecessary well visits, and automate repetitive tasks to free up time.

Reduce Costs

Prevent unnecessary well damage and failures, extend asset life, avoid downtime with early anomaly detection, and track intervention impacts on production.

Improve Production

Minimize production anomaly impacts, balance reservoir inflow with pump settings, and reduce deferred production.

Reduce Emissions

Reduce your environmental impact through enhanced optimization.

Industry Trusted

Proven Results

With nearly 200,000 BOE/D managed on our platform, we help companies achieve significant production gains and improve productivity, cost savings, and emissions reductions. These results are not just theoretical—they are backed by real-world data and success stories from our clients.

Our case studies provide detailed insights into the substantial benefits our platform has delivered, showcasing the tangible impact of our solutions.

Surveillance and Analytics

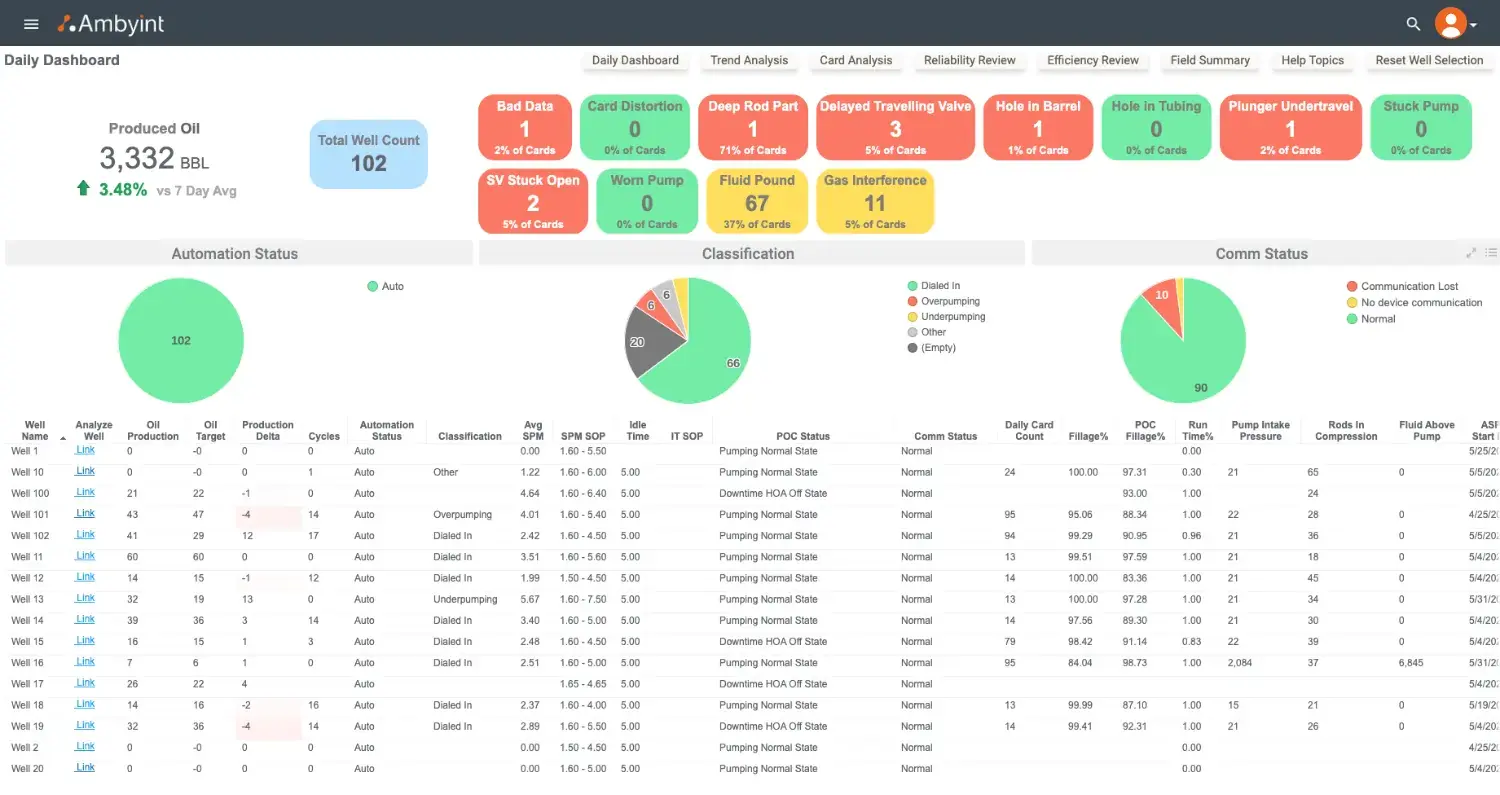

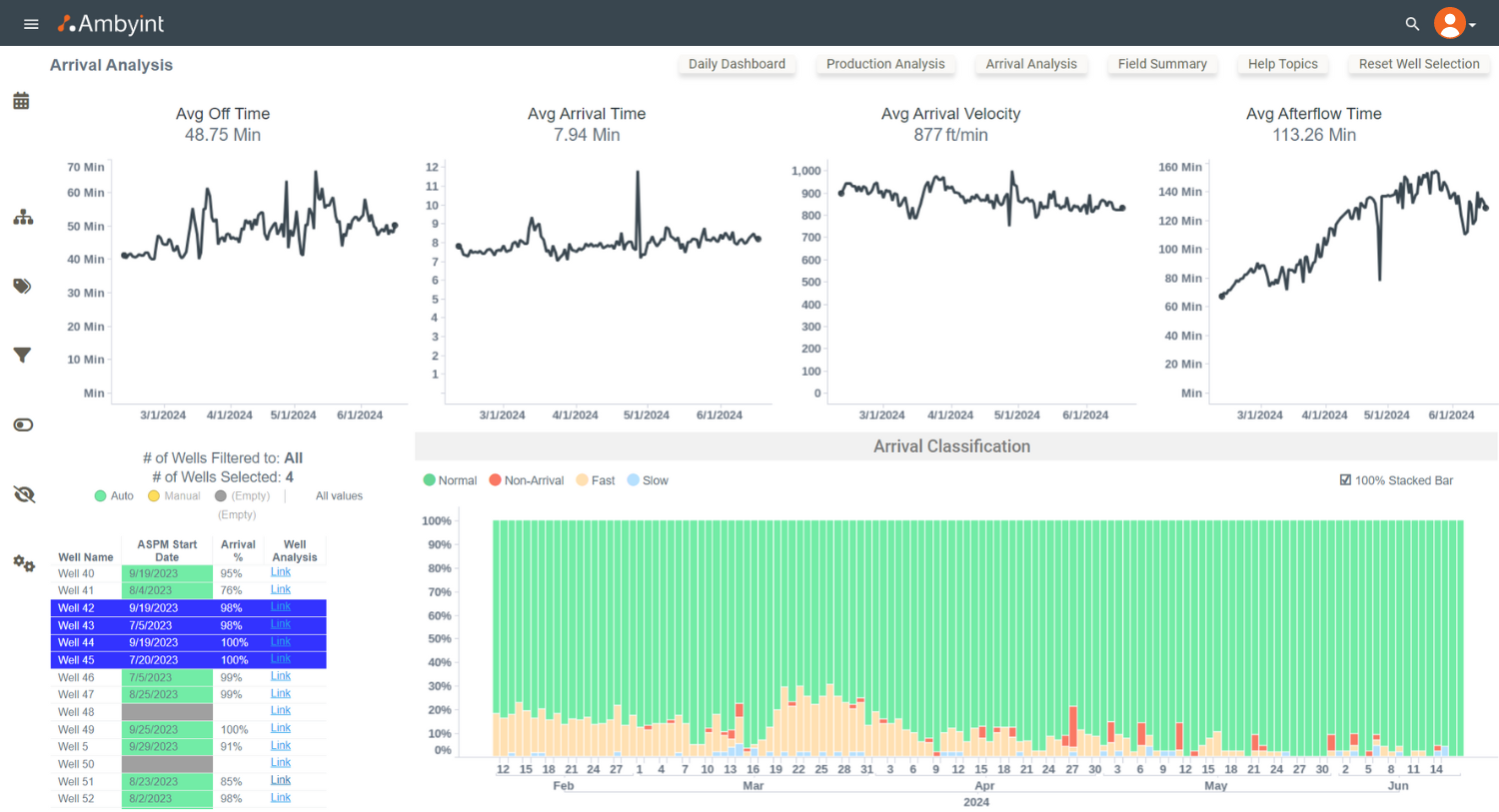

Our advanced analytics provide a more comprehensive view of production optimization, giving production employees greater visibility into the state of their well.

-

Automated reports for informed decision-making

-

Dashboards for quick issue identification and day planning

-

Review key performance metrics for lift systems across all wells over time

-

Monitor impact of ASPM over time for a single well or customizable well groupings

Anomaly Detection and Predictive Maintenance

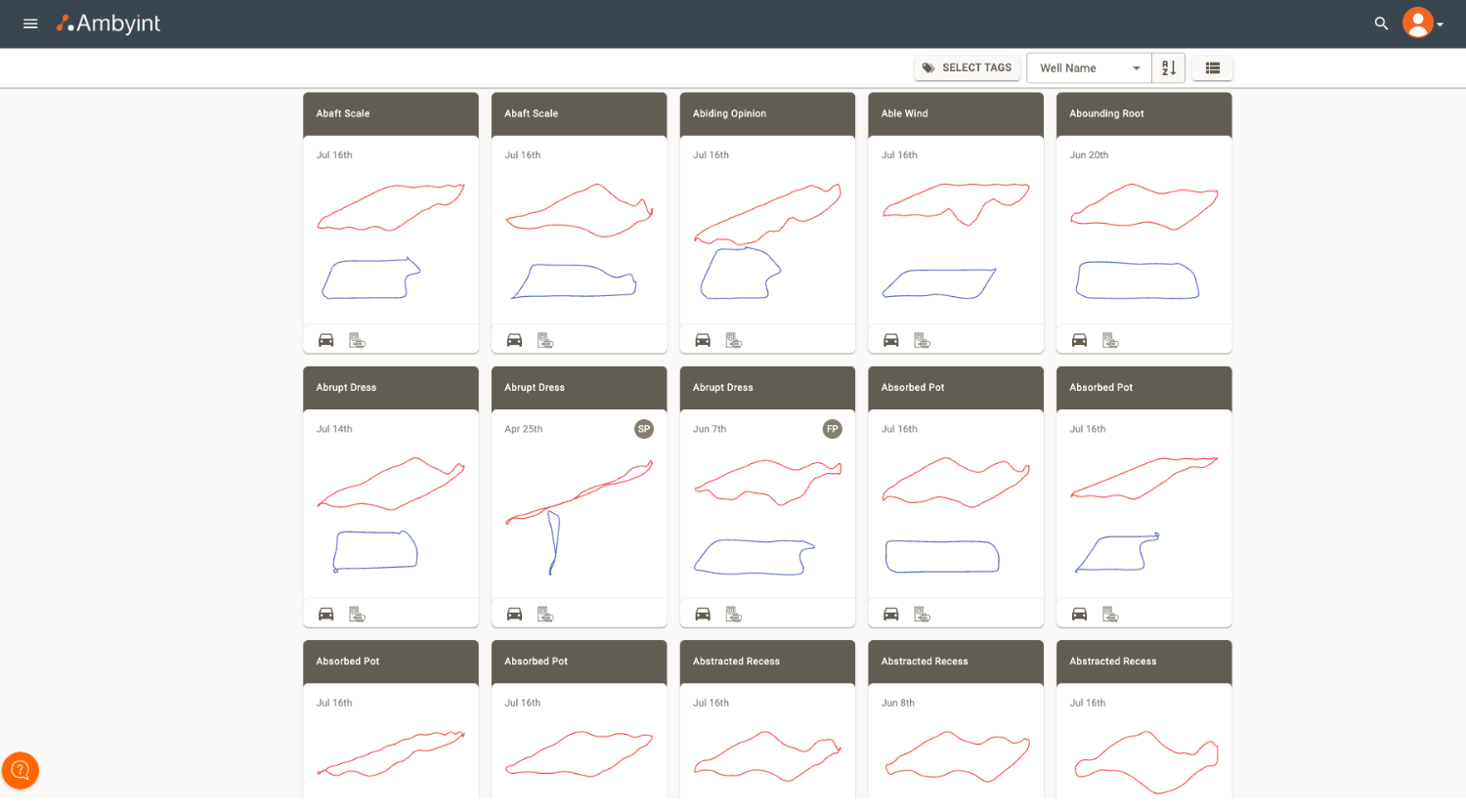

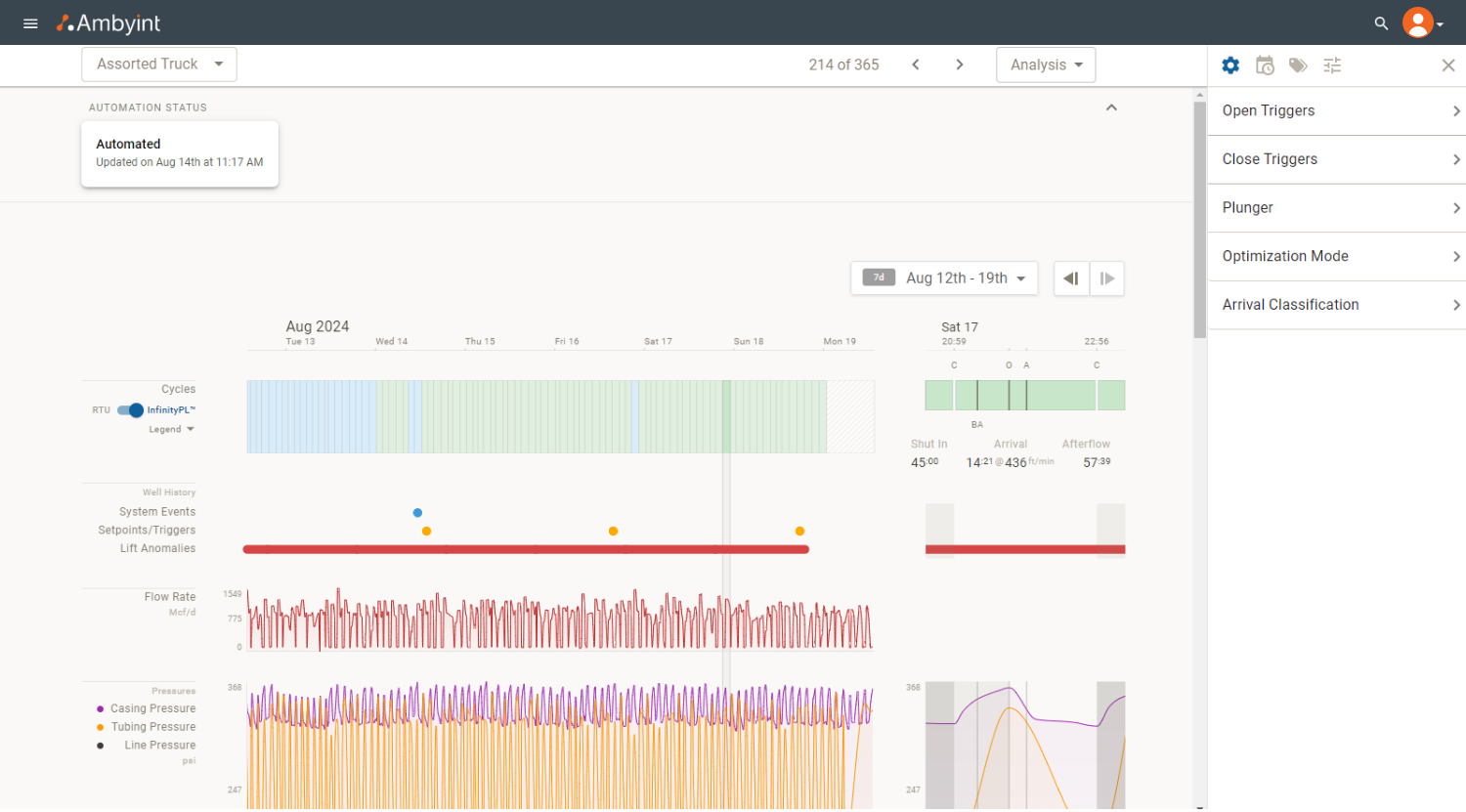

Our platform uses advanced AI to monitor equipment health and identify surface and downhole problems quickly, reducing the cycle time between an issue happening in the field and a resolution.

-

Identifies downhole issues prior to failure

-

Enhances workover planning lead times

-

Improves well design decision-making with downhole insights

Autonomous Setpoint Management

Our physics-informed AI classifies well optimization states and determines optimal setpoints. This feature includes:

-

Daily classifications of wells based on artificial lift type that define optimization strategy

-

Optimal controller setpoint recommendations for review and manual or autonomous updates

-

User defined parameters and boundary conditions to ensure the well is always operating within expected limits

-

Remote or autonomous setpoint updates directly through existing SCADA infrastructure

System Compatibility

Ambyint’s platform is designed to integrate seamlessly with existing systems, providing:

-

Compatibility with all major production accounting and SCADA platforms

-

Support for a wide range of pump off controllers (POCs) and remote terminal units (RTUs)

-

Secure data transport and storage in full compliance with annually audited SOC 2 Type 1 and Type 2 reports

Innovative Approach

How We Do It

By combining physics-informed models, SME insights, and advanced AI, our platform provides exceptional value to lean oil & gas teams, enabling them to optimize every well, every day.

-

Physics-Informed

Starting with well-established physics principles.

-

Subject Matter Experts

SMEs with deep application knowledge and field experience.

-

Artificial Intelligence

Data science engineered for production optimization.

HEAR FROM OUR CUSTOMERS

TESTIMONIALS

– Phil Espinoza, Production Optimization Foreman

“InfinityRL enables Chord Energy to monitor more wells better and faster than XSPOC.“

– Optimization Technician

“I really like Ambyint. It makes my job way easier now and I have to spend less time looking for problem wells.”

– Jack Freeman, Production Engineer for Equinor’s Bakken Asset

“The Ambyint technology has improved the remote data visibility and has delivered a more accurate diagnostic of downhole conditions to our rod pump wells in the Bakken.”

Field Proven Results

Proven Impact

Our case studies highlight significant production increases, cost reductions, and enhanced operational efficiency, providing proven results of the transformative impact our solutions have on well operations.