Customer Background

A prominent energy corporation specializing in the exploration and production operations for crude oil and natural gas resources.

- Basin: Bakken

- Number of Wells: 800 wells

- Deployment Time: 2020 – present

Main Challenges in Rod Lift Optimization

The customer was looking for a solution to standardize and scale effective rod lift setpoint optimization to stabilize production rates and reduce the mean time between failures. Traditional solutions were unable to deliver the desired results without substantial engineering and operations resources.

Solutions

Implementing Ambyint’s Solution

After thoroughly evaluating their current processes, this operator implemented Ambyint’s InfinityRL rod lift optimization solution, which includes improved optimization surveillance, automated reporting, dynacard-based anomaly detection, and Autonomous Setpoint Management (ASPM). These offered unique features that other alternatives did not, such as automatically adjusting minimum and maximum SPM setpoints on VFD-enabled wells.

Autonomous Control & Optimization

Ambyint’s solution utilizes physics calculations, operational parameters, and artificial intelligence to increase system reliability and efficiency on overpumping wells and to increase production on underpumping and gas interference wells. ASPM classifies each well as dialed-in, overpumping, underpumping, or gas interference. Based on that classification, the solution then adjusts SPM or idle time settings accordingly.

Industrial Context

Traditionally, oil and gas companies have divided into two camps when attempting to optimize wells without tools like ASPM. One is that they rely on physics calculations, which is what most legacy software focuses on. This school of thought is limited by its reliance on fallible assumptions and lack of nuance.

The second school of thought depends on legacy knowledge and subject matter experts (SMEs) leaning into past successes and rules of thumb. This method’s limitation is that it requires a lot of trial and error. The wins can be productive, but the necessary losses to get there can be extensive, making the system overall inefficient.

Ambyint’s tools supplement both methods, filling in the inevitable gaps and inefficiencies with artificial intelligence capabilities to augment and improve team members’ efforts.

The benefit of these tools can be seen in how overpumping and underpumping were both corrected at scale, showing a clear impact for this firm’s most recent 200 well deployment.

Results

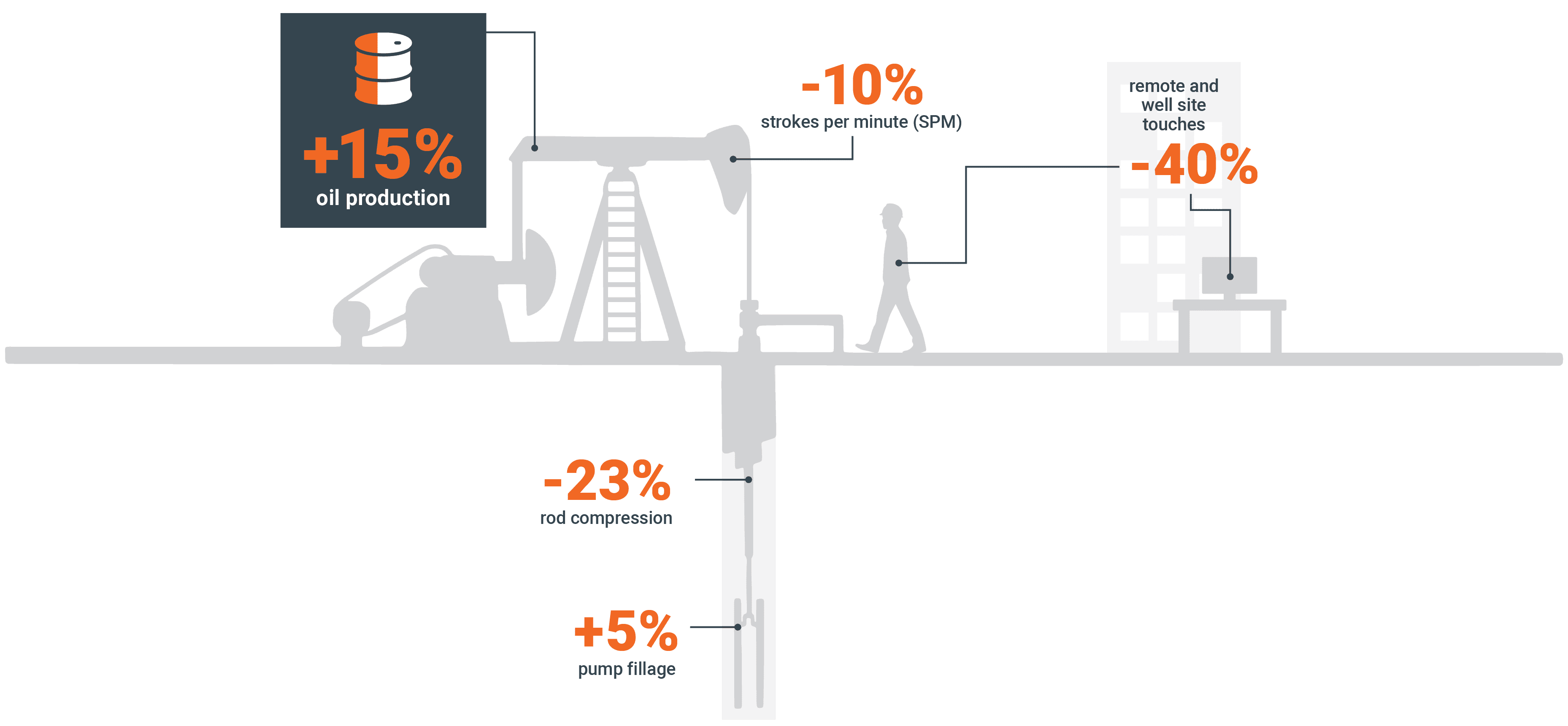

The implementation of Ambyint’s InfinityRL rod lift optimization solution across 200 wells delivered significant operational improvements for the global independent energy company:

- Production Increases

Average production increased by 15% across the optimized wells - Improved Efficiency

Average pump strokes per minute (SPM) decreased by 10%

Average downhole pump fillage increased by 5%

Instances of detrimental rod compression decreased by 23% - Reduced Maintenance & Interventions

InfinityRL reduced “well touches,” including remote interventions and wellsite visits by 40%

The scaled deployment of InfinityRL rod lift optimization solution delivered consistent optimization across the operator’s assets without relying on limited human resources.

Ambyint’s AI capabilities supplement and enhance engineering teams’ efforts, enabling them to achieve superior results beyond what traditional methods alone could accomplish.

Other key benefits of InfinityRL rod lift optimization solution include reduced downtime risk, decreased repair costs, and increased workforce productivity by automating previously manual processes.

Interested in learning more about Ambyint’s solutions and what they can do to improve your operations? Contact us now.