InfinityRL™ Solution

Ambyint’s InfinityRL rod lift optimization solution delivers leading edge optimization and diagnostics capabilities for rod lift wells. The solution is data-source agnostic, meaning it’s compatible with all robust SCADA systems to enable rapid deployment of large fields of rod lift wells. InfinityRL improves visibility into equipment operating conditions, reduces time spent surveilling and analyzing wells, and automates key well optimization workflows to enable improved workforce efficiency and scalability.

Ambyint’s InfinityRL technology utilizes a differentiated approach, combining physics-based models with SME insights and artificial intelligence to deliver value to customers. The autonomous, closed-loop control of key pump-off controller setpoints significantly reduces the need for manual surveillance and optimization workflows, while custom, automated reports ensure that operations staff receive concise summaries of critical information directly to their inboxes. Ultimately, InfinityRL’s rapid optimization system provides robust analytics and reporting capabilities, anomaly detection, and autonomous setpoint optimization for improving workforce efficiency and production.

Customer: Chord Energy

Chord Energy is an independent oil and gas company operating in the Bakken and Three Forks plays in North Dakota and Montana. With a commitment to energy, community engagement, and technological innovation, Chord Energy aims to drive positive change in the energy industry.

- Industry: Oil and Gas

- Basin: Bakken

- Number of Wells: 2,500

- Project Timeframe: 2022 to present

- Website: https://www.chordenergy.com/

Challenges

Chord Energy faced challenges in optimizing production efficiency across their oil wells. Previous solutions failed to deliver desired results, prompting the need for a comprehensive solution that could improve operational efficiency, reduce failure rates, and save on operational costs.

“I really like Ambyint. It makes my job way easier now and I have to spend less time looking for problem wells.”

Optimization Technician

Deployment

Chord deployed Ambyint’s InfinityRL technology on 2,500 rod lift wells via a SCADA integration. This included approximately 2,400 VFD/POC wells to optimize min/max SPM, and ~100 POC wells to optimize idle time. No additional hardware was required for the Ambyint deployment; it was purely a software connection with Chord Energy’s existing systems.

“We were initially looking into an AI system to help us with the optimization because we didn’t want to put any hardware in the field. With Ambyint’s software-only platform, we were able to do everything on the back-end. The Ambyint team was crucial in getting that system up and running alongside our existing system. They’ve been super supportive and very available the whole time. It’s been pretty seamless; they got their system online pretty fast and we didn’t have to do much of a lift to get the wells set up in the platform, updated, and all of the equipment running. They also helped us set safe operating parameters so we didn’t have to go well by well.”

Phil Espinoza

Production Optimization Foreman at Chord Energy

This deployment aimed to:

- Provide improved analytics and reporting for both operations and engineering staff

- Reduce the number of man hours for various operations and engineering staff via our autonomous optimization capabilities and card-based anomaly detection

- Increase production and reliability

Outcomes

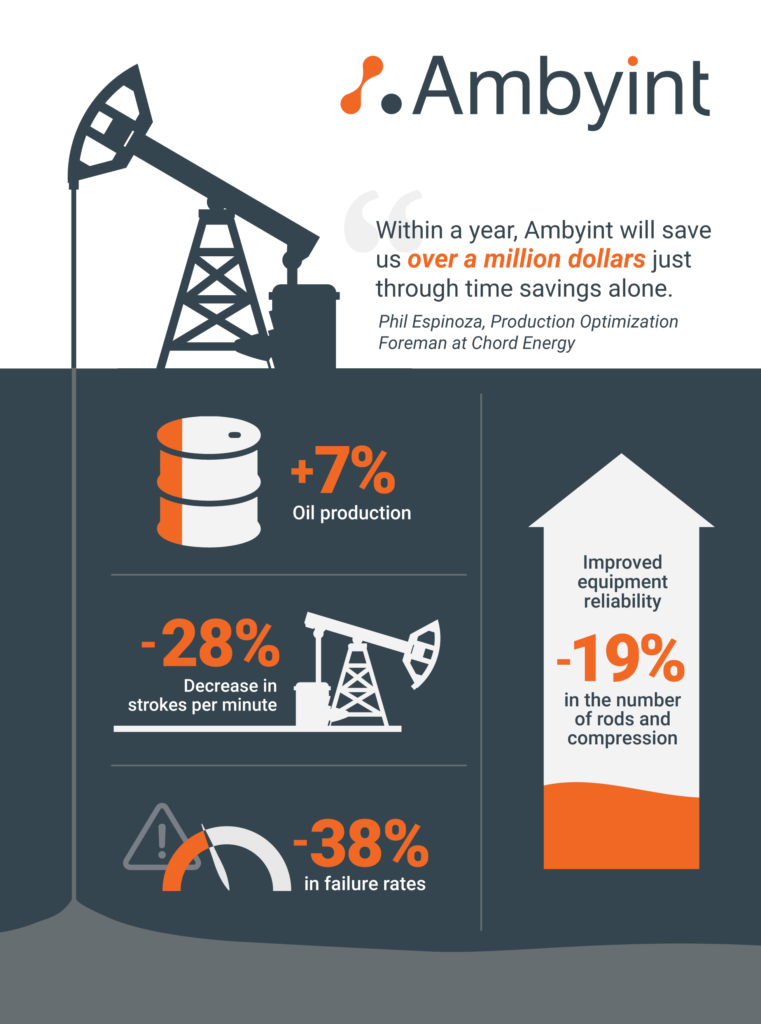

The deployment of InfinityRL improved Chord’s monthly oil production by 7% and liquid production by 19% over a 6-month period. For underpumping wells, monthly oil production increased by 14%.

It also reduced costs, with a strokes per minute (SPM) reduction of 6% in the same 6-month period. When measured from the beginning of the Ambyint deployment, InfinityRL reduced SPM by 28%. Additionally, equipment reliability was improved through a 19% reduction in the number of rods in compression.

Notably, Ambyint reduced failure rates by 38% in Chord’s field. After launching an initiative to improve failure rates in 2022, Chord saw their fleet-wide failure frequency fall drastically. Although not the sole driver, Ambyint played a key role in improving reliability on wells to which it was deployed.

Ultimately, the implementation of Ambyint’s InfinityRL technology enabled Chord to automate repetitive manual processes, improve their workforce efficiency and scalability, reduce well optimization and diagnostics time, promote environmental sustainability, minimize wellsite visits, and reduce operational costs. The Chord team concluded that Ambyint enabled roughly $1 million in annual labor cost savings through the reduction of manual workflows.

“Within a year, Ambyint will save us over a million dollars just through time savings alone of our technicians. Instead of them sitting in front of their computers in the office, they can be where they really want to be: out in the field, putting their hands on the equipment. Those are some big benefits for us.”

Phil Espinoza

Production Optimization Foreman at Chord Energy

Be Our Next Case Study

Now it’s time for you and your team to experience the transformative power of Ambyint’s InfinityRL technology yourself. Contact us today to learn more and embark on a journey towards enhanced efficiency, lower operational costs, supporting lean teams to do more, and sustainability in oil and gas production.