Customer Background

Encino Energy is an oil and gas operator focused on the sustainable development of its assets in the Appalachain Basin. With a strong focus on innovation and performance, Encino is continuously seeking ways to improve operations through digital technologies and AI-driven strategies.

- Industry: Oil and Gas

- Basin: Appalachian Basin

- Number of Wells on the Ambyint platform: 344

- Project Timeframe: 2023 to present

Main Challenges:

Encino faced growing pressure to optimize an expanding portfolio of plunger lift wells with a limited operations team. Traditional manual tuning approaches required significant time and effort, yet delivered inconsistent results, especially across later-lifecycle wells that were no longer producing efficiently. These wells often received less attention due to the team’s capacity constraints, which led to missed opportunities for optimization. Encino needed a solution that could scale optimization beyond what the operations and optimization team could manually manage. They were looking for a way to reduce the burden on lease operators, improve training by giving new team members visibility into past performance trends, and ultimately shift more wells into “cruise control” mode—where AI could manage day-to-day optimization reliably and consistently.

Solutions:

To meet these challenges, Encino deployed Ambyint’s InfinityPL platform, a purpose-built AI-powered plunger lift optimization solution. The platform replaced manual, reactive tuning with an autonomous, data-driven approach. By combining real-time surveillance, anomaly detection, and autonomous setpoint control, Ambyint enabled Encino to optimize wells around the clock, at scale. Operators were able to monitor performance and intervene only when necessary, freeing up time to focus on unique or complex well issues. The centralized dashboards gave both experienced and new lease operators access to critical insights, such as well history and performance trends, which enhanced operator training and overall team effectiveness. The automation not only supported field teams but also allowed optimization to be economically extended to lower-producing, late-life wells that previously fell outside the team’s reach.

Key Outcomes

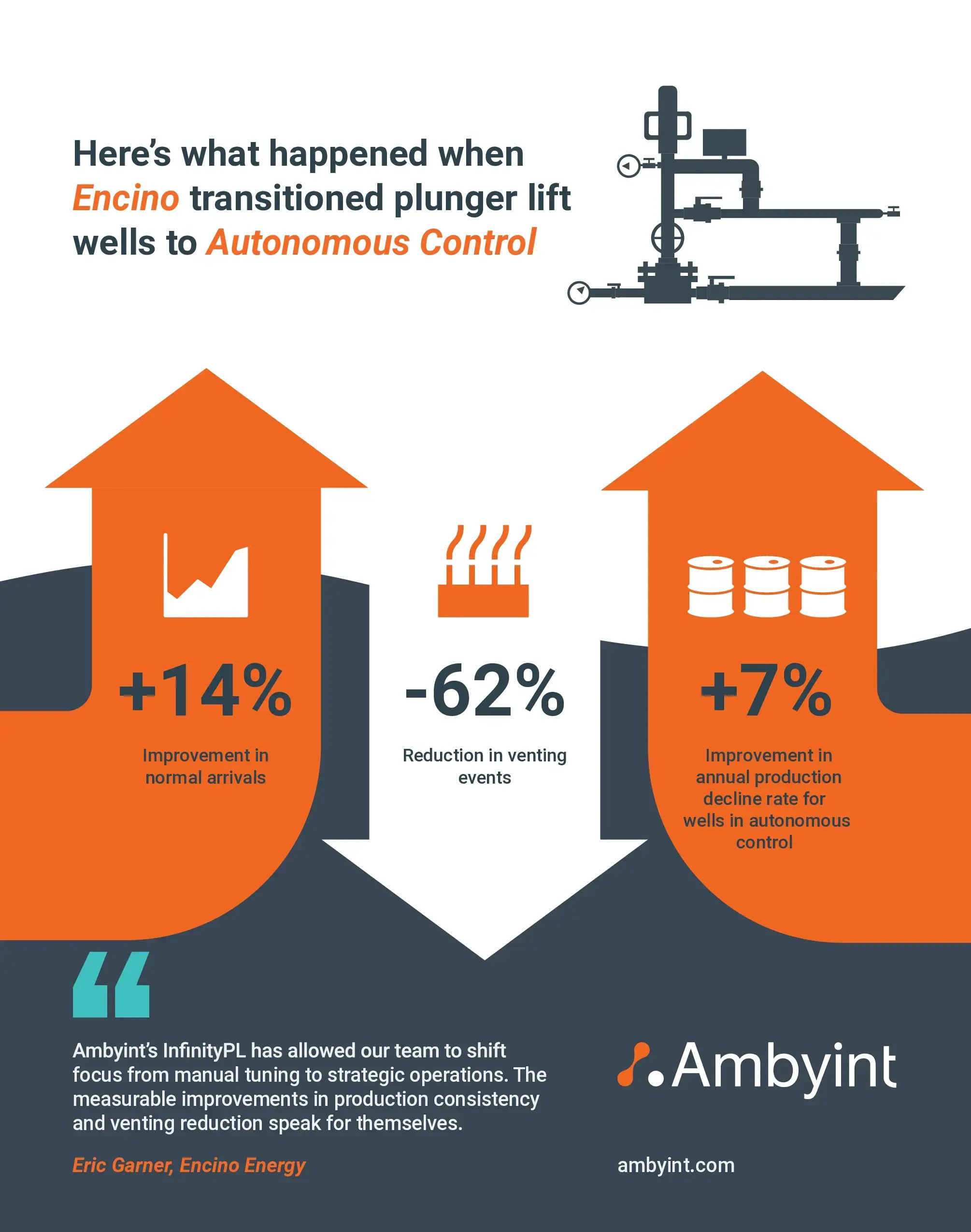

Encino Energy saw significant improvements after transitioning wells to autonomous control mode ("auto” mode):

- Annual production decline improved by 7% across a pilot group of autonomous control wells compared to manually optimized wells

- Since initial deployment, the solution has implemented 169,024 setpoint changes

- First Continuous run/2-Piece plunger deployment completed, enabling autonomous optimization through all plunger types

- Normal arrivals improved by 26% in the initial pilot, with full-scale development showing a 14% improvement - 23% higher than the manual well group overall

- In full-scale deployment, decline rate improved by 1% based on exponential decline curves (from 10% to 9%)

- Straight-line decline improvement by 10% (manual: 19%, auto: 9%)

- Venting events were reduced by 62%, aligning with Encino’s emissions reduction strategy

These results highlight the significant impact that Ambyint’s InfinityPL platform has on production consistency, operational efficiency, emissions reduction, and field team productivity.

“Ambyint’s InfinityPL has allowed our team to shift focus from manual tuning to strategic operations. The measurable improvements in production consistency and venting reduction speak for themselves.”

Eric Garner

Manager, Production Engineering, Encino Energy

A Promising Partnership

Encino’s experience with Ambyint underscores the value of leveraging AI to support lean field teams, optimize every well affordably, and extend automation to wells that might otherwise be left behind. The InfinityPL platform not only delivered measurable production, but also helped build workforce capacity by simplifying operations and enhancing training.

To discover how Ambyint’s InfinityPL can drive similar results for your operations, contact us today.

.