Situation

Rod Lift Optimization

Two thirds of E&P company’s rod lift wells were overpumping causing higher failure rates and excessive electricity costs. The company had more wells than operations staff to focus on daily optimization needs, which led to a search for technology provider offering the following:

- Real-time operational visibility

- Automated controller optimization

- Predictive maintenance

- Operational scale

Solution

Ambyint InfinityRL™

Ambyint deployed its rod lift optimization solution across E&P company’s Eagle Ford asset establishing connectivity at remote well locations, providing high resolution dynamometer cards, delivering AI-based setpoint recommendations, and automating controller updates.

Engineers became more efficient avoiding time-consuming data gathering and analysis. With automated well optimization and greater span of control, engineers shifted focus to other high value activities.

Results

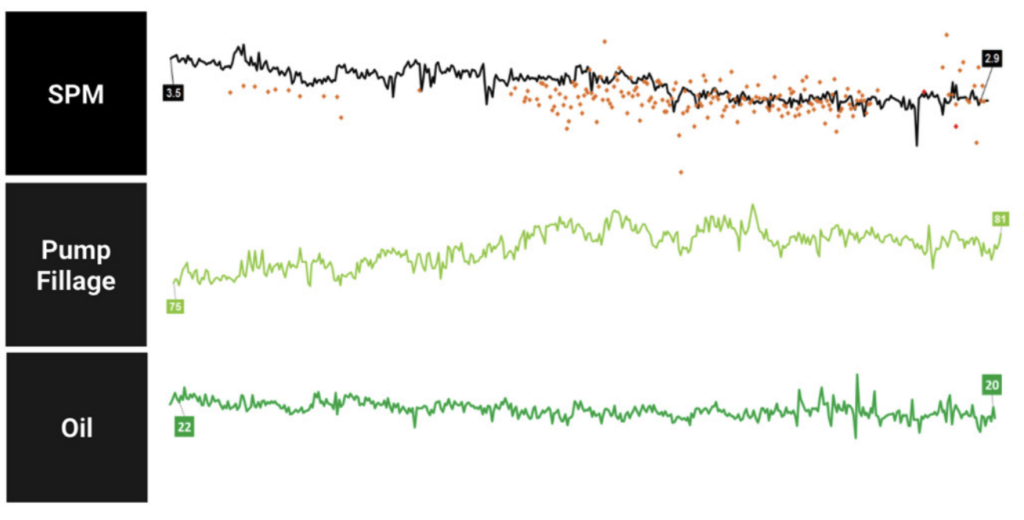

Optimized production translated into less energy expended, lower costs, and increased revenue with

operational team exerting greater management control over more wells on a daily basis.

6% ⇧

Production volumes for underpumping wells

17% ⇩

Strokes per minutes (SPM)

11% ⇩

Power consumption

13% ⇩

Emissions